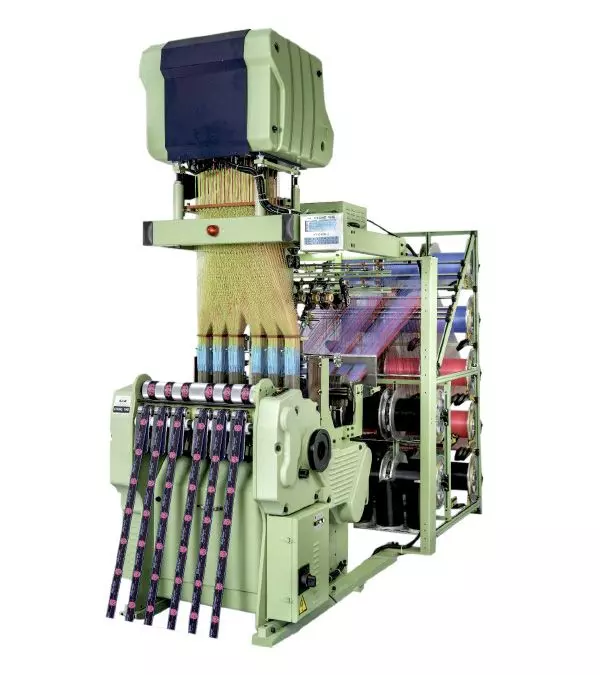

Swiss Type Narrow Fabric Weaving Machine Series

NDF

Narrow weaving machine, narrow looms, flat-head needle loom

The Swiss Type Narrow Fabric Weaving Machine features a flat head shuttleless design and reverse tension spring mechanism for precise, smooth weaving performance. Suitable for narrow fabrics, plaid ribbons, and webbings below 2mm thickness, it offers a weaving width from 20mm to 220mm and weft density between 3.1cm and 40.5cm. CE-certified for safety and durability, this model ensures stable high-speed production, ideal for apparel, footwear, bag, and industrial webbing manufacturing.

Swiss Type Narrow Fabric Weaving Machine Series — Precision Weaving Applications

Elastic and non-elastic band, curtain heading tapes, bra straps, plain ribbon and printed label, bandage, lumbar support belt, chest belt, etc.

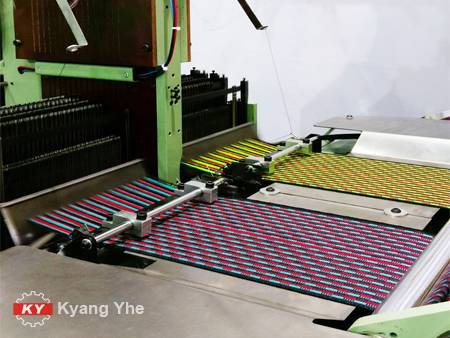

Live Demonstration of NDF Narrow Fabirc Weaving Machine

- Cam System

- The shedding frame lifts to form the opening; the weft is inserted and beaten to shape the fabric.

- Smooth yarn feeding with consistent tension.

- Auto stop on fault detection.

Operating Principle|Precision, Stability, and Efficiency

During operation, the Swiss Type Narrow Fabric Weaving Machine synchronizes multiple mechanical systems to achieve stable and precise weaving performance. The main drive and cam transmission convert rotational motion into linear movement, driving the shedding frame to lift and separate warp yarns, forming a clear and wide shed. The weft insertion system then passes the weft thread through the shed with balanced tension, while the reed mechanism beats the weft tightly to maintain fabric density. A covered tension spring assembly absorbs vibration and ensures consistent tension on warp yarns during high-speed operation. Meanwhile, the micro-switch detection unit monitors machine status and instantly stops the loom in case of yarn breakage or power fluctuation, protecting both machine and fabric integrity. Together, these systems deliver smooth motion, high-speed stability, and consistent weaving quality for fine and narrow fabrics.

Core Features of NDF Narrow Fabric Weaving Machine

- Reinforced Structure for Stable High-Speed Operation – The machine base and side plates are built with an integrated floor-standing structure to enhance rigidity and reduce vibration, ensuring stable, continuous production at high speed.

- Low-Noise Drive System for Long-Term Durability – A universal-type cutter reduces mechanical load and noise during operation, providing smoother running performance and extending machine lifespan.

- Optimized Dobby Frame Design for Better Weaving Efficiency – The dobby frame is moved forward by 10mm to enlarge the fabric opening, shortening setup time. The upper guide plate keeps warp tension uniform, producing flat and consistent webbings.

- Extended Spring Design for Greater Cushioning and Stability – The elongated, covered tension spring design enhances buffering force, improves durability, and minimizes tension fluctuation during high-speed weaving.

- Eco-Friendly Safety Design with CE Certification – The protective cover is made of eco-friendly ABS material with a reinforced front cover, improving safety and appearance. Fully CE-certified to meet international safety standards.

- Precise Yarn Control for Enhanced Webbing Quality – A micro-switch power-off detection system increases sensitivity, while the spring-steel yarn guide ensures smooth yarn passage and prevents fluffing, resulting in finer webbing quality.

🔹Specification Table|NDF Model Details

| MODEL | TAPE LINES | REED WIDTH | HEALD FRAME | PICK PEPEAT | MAX. POWER | R.P.M | REMARK |

|---|---|---|---|---|---|---|---|

| NDF 2/135 | 2 | 135mm | 14-16 | 48 | 1.5KW | 600-800 | |

| NDF 2/165 | 2 | 165mm | 14-16 | 48 | 1.5KW | 600-800 | |

| NDF 2/220 | 2 | 220mm | 14-16 | 48 | 1.5KW | 400-500 | INVERTER |

| NDF 4/65 | 4 | 65mm | 16-18 | 48 | 1.5KW | 1200-1400 | |

| NDF 6/45 | 6 | 45mm | 16-20 | 48 | 1.5KW | 1200-1400 | |

| NDF 6/50 | 6 | 50mm | 16-20 | 48 | 1.5KW | 1200-1400 | |

| NDF 8/27 | 8 | 27mm | 16-20 | 48 | 1.5KW | 1200-1400 | |

| NDF 10/20 | 10 | 20mm | 16-20 | 48 | 1.5KW | 1200-1400 | |

| NDF-TDM 4/65 | 4 | 65mm | 14 | 40 | 1.5KW | 750-900 | TDM Checker Tape |

| NDF-TDM 6/45 | 6 | 45mm | 14 | 40 | 1.5KW | 750-900 | |

| NDF-TDM 8/27 | 8 | 27mm | 14 | 40 | 1.5KW | 750-900 |

Optional Function Device

- Double take off roller

- Single take off roller

- Double weft double latch needle

- Double weft single latch needle

- Double warp picot

- Double weft picot system

- Double weft double binder

- Double weft single binder

- Single weft single binder

- Single weft double binder

- Extra large shedding lever

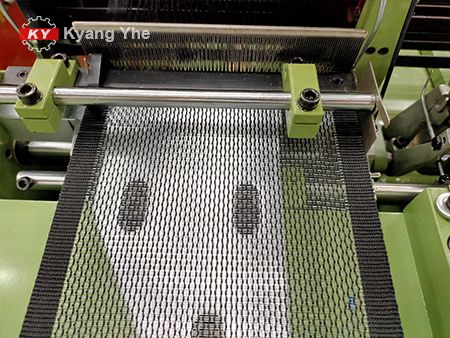

- Leno attachment

- Rubber feeder

- Back take off device

- Front take off device

- CE Certification

- Double-decker device

- Double weft and double latch needle for curtain tape device

- Check tape device

📌Why Choose NDF – Precision, Stability, and Expertise in Thin Webbing Weaving

Stable Transmission Structure for High Weaving Accuracy

The NDF narrow fabric weaving machine adopts a Swiss Type flat-head shuttleless design with a cam transmission system, converting rotary motion into precise linear movement for accurate warp and weft control. The floor-mounted frame structure enhances rigidity and minimizes vibration, ensuring consistent tension during long-hour operation. The covered tension spring and micro-switch monitoring system further stabilize production and improve fabric uniformity and surface quality.

Specialized for Thin and Delicate Webbing Applications

The NDF Series is engineered for webbings under 2 mm thickness, ideal for plaid ribbons, elastic tapes, shoelaces, garment webbings, and bag straps. With a weaving width range of 20 mm – 220 mm and weft density from 3.1 cm – 40.5 cm, it offers flexible configurations to meet diverse product requirements—an optimal solution for thin and high-precision narrow fabrics.

High Stability with Low Maintenance Costs

The machine is equipped with an eco-friendly ABS protective cover and complies with CE international safety standards. Modular part design simplifies maintenance, while the use of standardized cutters and yarn guides reduces replacement frequency, minimizes downtime, and lowers overall maintenance costs for long-term efficiency.

Global Service Network to Ensure Continuous Production

Kyang Yhe provides a worldwide network of authorized agents and service centers, offering on-site maintenance, spare-part supply, and operator training. Customers can access local technical support quickly, ensuring stable machine performance and minimizing production interruptions.

Spare Parts and Technical Support

If you require spare parts for your KYF needle loom, please fill out the Spare Parts Inquiry Form and provide your machine ID number along with the relevant part numbers from the manual. To help us serve you faster, please include the quantity, photos, or a sample of the required parts. Our business specialists will assist you promptly to ensure minimal downtime.

📨 Need Technical Support or Equipment Advice? Please fill out our online inquiry form to contact Kyang Yhe, or download our EDM to learn more about detailed product specifications.

- Gallery

- KY Narrow Fabric Weaving Machine Spare Parts for Tape Plate Bracket.

- KY Narrow Fabric Weaving Machine Spare Parts for Tape Plate Bracket.

- KY Narrow Fabric Weaving Machine For Fold Over Elastic.

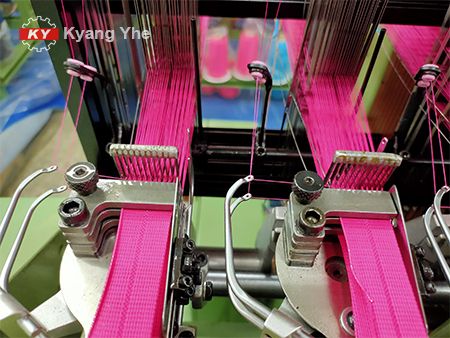

- KY Narrow Fabric Weaving Machine For Plaid Ribbon.

- KY Narrow Fabric Weaving Machine For Bra Straps.

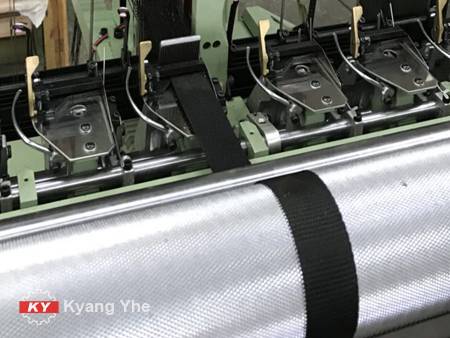

- KY Narrow Fabric Weaving Machine For PP ribbon.

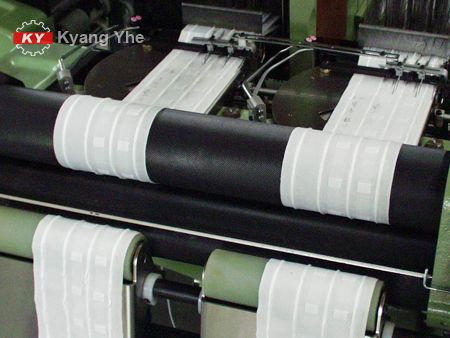

- KY Narrow Fabric Weaving Machine For Curtain heading.

- KY Narrow Fabric Weaving Machine For Curtain heading.

- KY Narrow Fabric Weaving Machine For Bandage.

- KY Narrow Fabric Weaving Machine For Elastic bandage.

- KY Narrow Fabric Weaving Machine For Medical Care.

- KY Narrow Fabric Weaving Machine For NDF2/220.

- Application

Curtain Heading Loom And Equipment

KY provides complete curtain heading tape production plan and technical consultant. High speed automatic needle loom produces high-quality curtain tape,...

Mattress Tape Loom And Equipment

KY provides complete mattress tape production plan and technical consultant. High speed automatic needle loom produces high-quality mattress tape, and with...

Ribbon Tape Loom And Equipment

KY provides complete ribbon production plan and technical consultant. High speed automatic needle loom produces high-quality ribbon tape, and with our one-stop...

Bandage Loom And Equipment

KY provides complete bandage production plan and technical consultant, Swiss type narrow fabric weaving machine produces high-quality bandage, and with...

Abdominal Support Binder Of Elastic Machine And Equipment

KY provides complete abdominal support binder production plan and technical consultant, Swiss type narrow fabric weaving machine produces high-quality...

Lumbar Support Belt Of Elastic Machine And Equipment

KY provides complete lumbar support belt production plan and technical consultant, Swiss type narrow fabric weaving machine produces high-quality lumbar...

Underwear Elastic Ribbon Loom And Equipment

KY customizes a complete "Underwear Elastic Ribbon Production Solution" and recommends best suited machine and purchase plan, to help you be successful...

Woven Label Loom And Equipment

KY customizes a complete "Woven Label Production Solution" and recommends best suited machine and purchase plan, to help you be successful in your business.Woven...

Twill Tape Loom And Equipment

KY provides complete twill tape production plan and technical consultant, the high speed automatic needle loom produces high-quality twill tape, and with...

Luggage Straps Loom And Equipment

KY provides complete luggage strap production plan and technical consultant. High speed automatic needle loom and jacquard loom machine produces high-quality...

Backpack Straps Loom And Equipment

KY provides complete backpack strap production plan and technical consultant. High speed automatic needle loom and jacquard loom machine produces high-quality...

Pet Leash Loom And Equipment

KY provides complete pet leash production plan and technical consultant, Wide and narrow computerized jacquard loom produces high-quality pet leash, and with...

- Related Products

Bonas Needle Loom Machine Series

KYF

Bonas needle loom machine series is designed for narrow fabrics up to 2 mm thick and 3–110...

DetailsMid-Heavy Automatic Narrow Fabric Ribbon Loom

KDN MG

Automatic Ribbon Loom production of tactical duty belt, cargo lashing, safety harness, etc....

DetailsMid-Heavy Narrow Fabric Needle Loom

ENM

ENM Mid-heavy narrow fabric loom series mainly produces medium-thick or heavy flat slings,...

DetailsProfessional Seat Belt Special Purpose Needle Loom Machine

NDF2/65

Professional Seat Belt Special Purpose Needle Loom also know as seat belt looms, for dedicated...

DetailsHook and Loop Strap Needle Loom Machine

NDV

Hook and loop strap needle loom machine is used for the production of hook and loop fasteners,...

DetailsSmart Data Collector for Narrow Fabric Weaving Machine

KY-OSDC

Through the smart data collector for narrow fabric weaving machine, real-time operation status...

DetailsIntelligent Active Electronic Warp Let-off System

KY-OEWC

Kyang Yhe's exclusive intelligent active electronic warp let-off system control system is designed...

Details- Files Download

NDF Narrow Fabric Weaving Machine

Download EDM know more about Kyang Yhe swiss type narrow fabric weaving machine

Download

Model

- NDF 2/135

- NDF 2/165

- NDF 2/220

- NDF 4/65

- NDF 6/45

- NDF 6/50

- NDF 8/27

- NDF 10/20

Reed Width

- 20

- 27

- 45

- 50

- 65

- 135

- 165

- 175

- 220

KY Needle Loom Catalogue 2025

Download E-Catalogue, know more about KY Needle Loom Equipment.

Swiss Type Narrow Fabric Weaving Machine Series | Durable Textile Machinery for Zipper, Label, Webbing - Kyang Yhe (KY)

Kyang Yhe (KY), founded in 1964 in Taiwan, manufactures high-quality Swiss Type Narrow Fabric Weaving Machine Series textile machinery. We specialize in narrow fabric jacquard looms, high-speed needle looms, heavy-duty weaving, braiding, and crochet machines. Get OEM/ODM customization, fast quotations, short lead times, and global service.

Our industrial machines run fast and stable, with easy maintenance. Applications include elastic and ribbon tapes, safety belts, luggage belts, and hook-and-loop. The lineup covers needle looms, narrow fabric weaving machines, label printing machines, and more—built for efficient, consistent production.

With 60+ years of experience, KY provides installation, training, spare parts, and after-sales support. Talk to our engineers today—request a free consultation or quote to choose the right machine for your line.