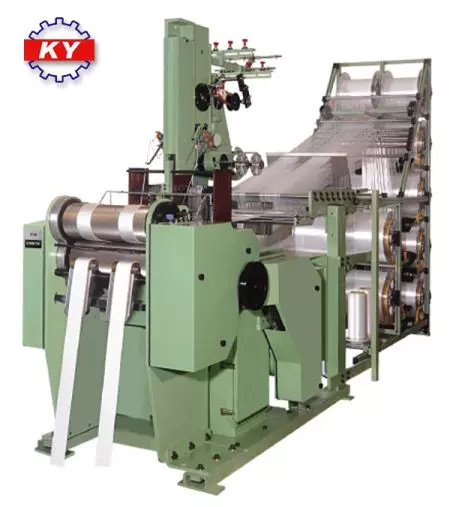

Lifting Slings Loom And Equipment

Lifting Slings Machine And Production Solutions

KY provides complete lifting slings production plan and technical consultant, Newly heavy narrow fabric needle loom produces high-quality lifting slings, and with our one-stop service, from warping, weaving to packing equipment to complete your product line.

Lifting slings are also called flat webbing slings, cargo slings or sling belt. The raw materials are made of polyester, nylon and polypropylene (PP yarn). The webbing produced varies in scope of application. When deciding what kind of sling to use, you must first know the scope of the lifting flat sling and the nature of the workplace, and consider the chemical factors that adversely affect the strength of the sling.

Lifting slings have multiple advantages such as high strength, wear resistance, oxidation resistance, and UV resistance. They are widely used in various fields. They are commonly used in aviation, aerospace, nuclear power establishment, military manufacturing, port handling, electrical equipment, and machinery Processing, chemical steel, shipbuilding, transportation and other fields. Click below right to fill out the form, KY's consultants will recommend the best production plan and equipment for you!

- GalleryRelated Machines

KY lifting slings loom can produce with customer's sample, including width, thickness, material, function and output. Make it easy for you to produce massively by auto control. Meanwhile guarantee the stability and quality.

Lifting slings are available with safety coefficient of 5:1, 6:1, 7:1 and 8:1. According to international standards, different colors are used to distinguish different lifting capacity slings. One stripe represents one ton, and it is easy to distinguish the lifting capacity of the sling.

The elongation rate of the flat belt of nylon raw material is 6~8% under safe load, and the polyester is less than 3%. Usually polyester is used in acidic environment, nylon is used in alkaline environment, and polypropylene has strong resistance to acidity, alkalinity and most chemical conditions. The working temperature range of the sling made of polyester fiber is -40℃~100℃. Under safe load, the elongation is less than 3%, and will return to the original original length after use, and the breaking elongation is 9-12%.

For more information about Lifting Slings Loom, including output, maintenance services or factory expansion solution suggestions, please fill in the online form and provide tape photos, tape width and thickness to supply the best service for you.