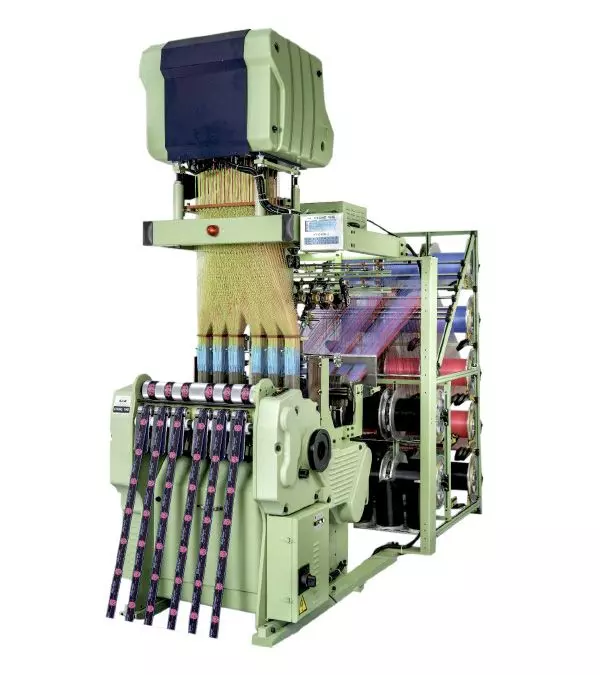

Professional Seat Belt Special Purpose Needle Loom Machine

NDF2/65

Seatbelt making machine, narrow fabric needle loom

Professional Seat Belt Special Purpose Needle Loom also know as seat belt looms, for dedicated to making seat belt webbing. Output ranges with 2 numbers of tape and width 65mm, the weft density is available from 3.1cm to 38.6cm in the CAM system to weave. Use EBRT device to adjust yarn tension, that manufacture the seat belt with high speed and productivity, precision is weaving heads for easy adjustment to meet the demand of high quality control, and comply with CE standards.

Application

Suitable for safety belts installed in automobiles and aerospace transportation. Such as seat belt harness, racing seat belts, dog seat belt.

Features

- Improve the high-speed operation stability of the machine, reduce the vibration of the machine, and strengthen the connection structure between the wall plate and the base.

- The shedding frame vertical bars on both sides are changed to an integrated shedding frame guide plate, which reduces the time for weaving and replacing shedding heald and improves work efficiency.

- Strengthen the operation stability of the shedding frame, the dropper device and other transmission structures, and improve the working life of the machine.

- Re-enforce weft needle, tape plate using needle bearing instead of roller bearing.

- Reinforced weft gear, increase the scale on the manual cylinder for facilitates the adjustment of the webbing.

- Increase stability of the cam, suitable for high performance.

- Increase the stability of yarn feeding, using aluminum wheel type transmission, double side lock.

- To increase the sensibility of dropper, the device has change to micro-sensor device.

- New humanity design cover on the take off roller, matches CE standard.

- To increase the rolling of the roller and the humanity operation, the roller has change from hollow cylinder to non-hollow cylinder with stair design.

Optional Function Device

- Weft Feeding Device

- CE Certification

Automatic Needle Loom Accessories

The seat belt needle loom quality parts what forward-displacing head frames makes for big shedding that ensures easy-use and high-efficiency. Universal shedding levers are shared, and low load, less noise and more steadiness coexist well. Guiding plate leads to a quality product without loss of efficiency. Both support walls are grounded to ensure steady running. Also, optional function devices are available.

Spare Parts Requirements

If you have needle loom spare parts requirements, please fill out the form by "Spare Parts Inquiry" and provide ID number of the machine. And also provide the part number according to the parts manual, the parts quantity, photos or provide a sample of the parts. Will be served by a business specialist.

| MODEL | TAPE LINES | REED WIDTH | HEALD FRAME | PICK PEPEAT | MAX. POWER | R.P.M | REMARK |

|---|---|---|---|---|---|---|---|

| NDF 2/65 | 2 | 65mm | 13 | CAM | 2HP | 1200 | EBRT |

*We have perfect machines that can produce seat belt webbing. According to the customer's sample, including width, thickness, material, application, function and output. Make it easy for you to produce massively by auto control. Meanwhile guarantee the stability and quality. Fill in the online form to learn more about Kyang Yhe or you can download EDM to know more about technical parameter data.

- Gallery

- KY Needle Loom Spare Parts for Weft Heads Holder.

- KY Needle Loom Spare Parts for Roller Lever Assem.

- KY Needle Loom Spare Parts for Tape Plate Bracket.

- KY Needle Loom Spare Parts for Tape Plate Bracket.

- KY Needle Loom Spare Parts for Chain Link Of Roller.

- KY Needle Loom For Seatbelt.

- KY Needle Loom For Seatbelt.

- KY Needle Loom For Seatbelt.

- Video

- Application

Seat Belt Loom And Equipment

KY customizes a complete "Seat Belt Webbing Production Solution" and recommends best suited machine and purchase plan, to help you be successful in your...

- Related Products

Swiss Type Narrow Fabric Weaving Machine

NDF

Swiss Type Narrow Fabric Weaving Machine application for high density and weaved smooth edge...

Details- Files Download

NDF2/65 Professional Seat Belt Special Purpose Needle Loom

Download EDM know more about Kyang Yhe seat belt needle loom

Download

Model

- NDF 2/65

Reed Width

- 65

KY Needle Loom Catalogue 2025

Download E-Catalogue, know more about KY Needle Loom Equipment.

Professional Seat Belt Special Purpose Needle Loom Machine | Maximize Output with Versatile High-Speed Braiding Machines

Kyang Yhe (KY), established in 1964 in Taiwan, is a premier manufacturer of high-quality textile machinery. Specializing in Professional Seat Belt Special Purpose Needle Loom Machine, needle loom machines, narrow fabric jacquard looms, heavy narrow fabric weaving machines, braiding machines, and crochet machines, KY delivers innovative and durable solutions to meet diverse industrial needs. With over 60 years of experience, KY is committed to providing advanced technology and reliable equipment to customers worldwide, ensuring superior production efficiency and quality.

Kyang Yhe (KY)'s industrial textile machines are designed to deliver high-quality knitted products such as elastic tapes, ribbon tapes, safety belts, luggage belts, and hook and loop fasteners. Their textile equipment is productive, high-speed, and easy to operate. The product range includes needle loom machines, weaving machines, label printing machines, weaving loom machines, and more, ensuring efficient and reliable textile production.

Kyang Yhe (KY) has been offering customers high-quality textile machinery since 1964. With advanced technology and 61 years of experience, Kyang Yhe (KY) ensures that customer demands are met effectively.