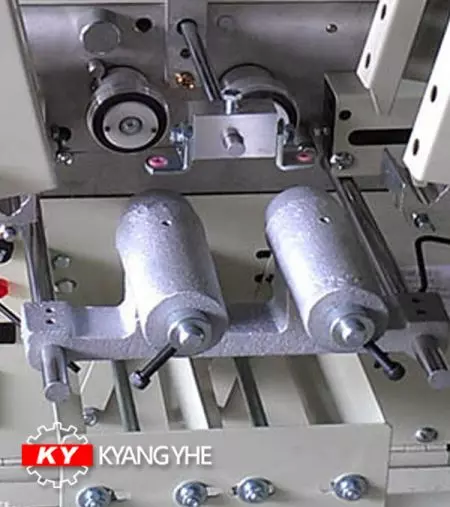

Bobbin Winder For Braiding Machine

KYTP02

Automatic Bobbin Winder is strong stability that can avoid the damage while unstable voltage. And working high speed, winding area is away from contamination to enhance productivity. The vending machine has automatic stop equipment, testing freely and shall automatically stop when yarn packing. Adopt an electronic counter to control winding floors, for changing yarn easily. The motor works stably to rank yarn, so the yarn shall be out easily and will reduce wastage of yarn.

Application

1. Suitable for different kind of yarns, such as label, knitted tape, lace, and cable line.

2. Available to work with Lace band machine, traditional braiding machine, and high speed automatic needle loom machine.

3. Suitable for various kinds of yarn, such as large / small chemical fiber, polyester, nylon, lurex yarn… etc.

Features

- Fully automatically PLC numerical value control, stable, and can prevent unstable voltage causing damage.

- High speed, winding area will not be polluted and improve production efficiency.

- Multi position automatic yarn break sensor device. The machine stop automatically when yarn break.

- Adopting imported electronic counter device which can control take-up layers and will not leave dead yarn to reduce yarn wearing.

- Motor drop in line evenly. Yarn outing easily and will not leave dead yarn, which will reduce yarn wearing.

Optional Function Device

- Counter device

Spare Parts Requirements

If you have spare parts requirements, please fill out the form with "Spare Parts Inquiry" and provide ID number of the machine. And also provied the part number according to the parts manual, the parts quantity, photos or provide a sample of the parts. Will be served by a business specialist.

| MODEL | TRAVERSE | SPINDLE | MAX. TAKE-UP O.D | SPEED | HP | POWER |

|---|---|---|---|---|---|---|

| KYTP02 | 113-140mm (Adjustable) | 2 | 48mm | 3500 RPM | 0.5HP×1, 15W×1,25W*1 | 220V/380V, 1HP |

- GalleryVideoRelated Products

Model

- KYTP02

KY Needle Loom Catalogue 2025

Download E-Catalogue, know more about KY Needle Loom Equipment.

Bobbin Winder For Braiding Machine | Maximize Output with Versatile High-Speed Braiding Machines

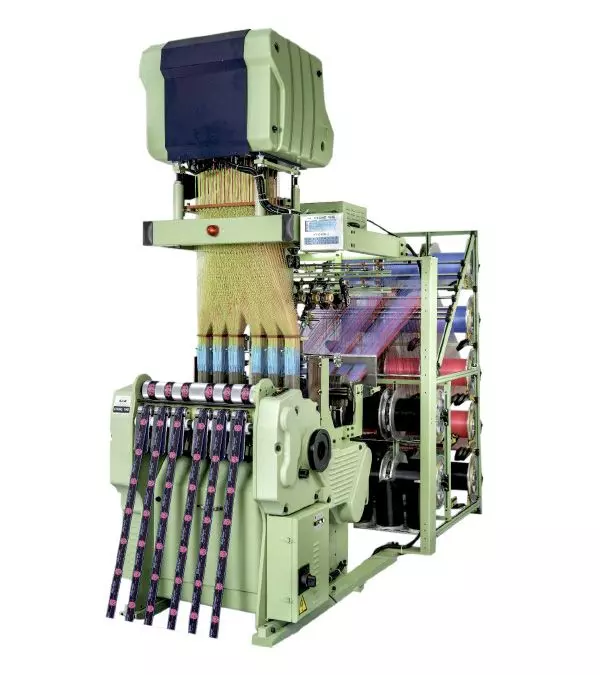

Kyang Yhe (KY), established in 1964 in Taiwan, is a premier manufacturer of high-quality textile machinery. Specializing in Bobbin Winder For Braiding Machine, needle loom machines, narrow fabric jacquard looms, heavy narrow fabric weaving machines, braiding machines, and crochet machines, KY delivers innovative and durable solutions to meet diverse industrial needs. With over 60 years of experience, KY is committed to providing advanced technology and reliable equipment to customers worldwide, ensuring superior production efficiency and quality.

Kyang Yhe (KY)'s industrial textile machines are designed to deliver high-quality knitted products such as elastic tapes, ribbon tapes, safety belts, luggage belts, and hook and loop fasteners. Their textile equipment is productive, high-speed, and easy to operate. The product range includes needle loom machines, weaving machines, label printing machines, weaving loom machines, and more, ensuring efficient and reliable textile production.

Kyang Yhe (KY) has been offering customers high-quality textile machinery since 1964. With advanced technology and 61 years of experience, Kyang Yhe (KY) ensures that customer demands are met effectively.