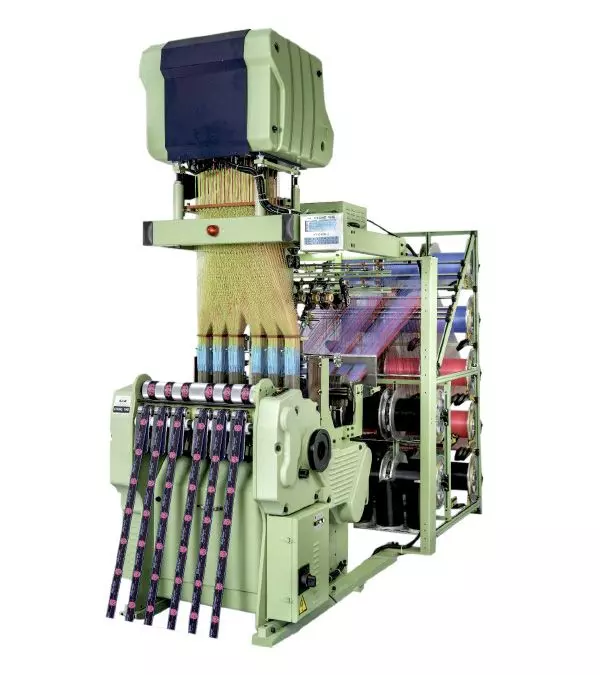

Particular Electron Frame Needle Loom Machine

KDN SF

Industrial webbing machine, tie back lanyard machine, narrow looms, seat belt needle loom

Electron frame needle loom is for producing shock absorbing lanyard, the weft density is available from 3.5cm to 36.5cm. Electron frame needle loom has attached electronic forms which with grounded wallboard is more solid to ensure steady running with the yarn transmission of middle pillar type, easy to operate.

Catch thread drives by cam automatically, suitable for high speed performance. Higher shedding lever for easy adjustment on the machine, also the side cover uses ABS material for environment protection and better outlook. And The electron frame needle looms most function parts has a patent for the invention of Kyang Yhe.

Application

Shock absorbing lanyards, tie back lanyard, harness lanyard, safety harness.

Features

- The stand and the side board are all in one structure to increase the stability.

- Total 12 shedding frames, the first 4 are control of servo motor, enable to adjust the shed lift freely, unlimited cycle, program the organization. The rest of 8 shedding frames are high shed lift for easy adjustment to produce.

- New tension control device can improve the yarn sending.

- Catch thread are drive by cam automatically, suitable for high speed performance.

- Reed stand are made by cast component, lighter and stronger, suitable for high speed performance.

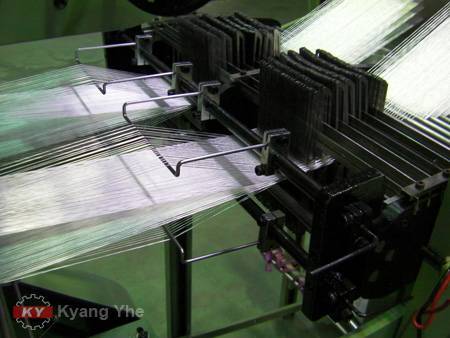

- Yarn feeding device are motivated from the center pillar to even the motion to increase the stability.

- Aluminum wheel type weft yarn feeder.

- Motor on the fixed axle, easier to adjust the motor.

- Single direction bearing FCB40 are used in the transmission.

- Shedding lever seal has changed to Nylon material for better performance in oil seal.

- Shedding lever spring is adjustable to production need.

- Side cover uses ABS material for environment protection and better outlook.

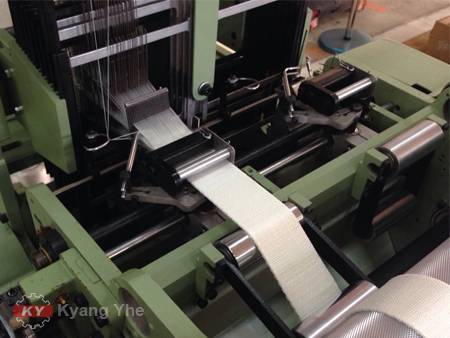

Automatic Needle Loom Accessories

Electron frame needle looms parts of catch thread are driven by cam automatically, suitable for high speed performance. And Reed stand is made by cast component, lighter and stronger. The yarn feeding device is motivated from the center pillar to even the motion to increase the stability.

Spare Parts Requirements

If you have needle loom spare parts requirements, please fill out the form by "Spare Parts Inquiry" and provide ID number of the machine. And also provie the part number according to the parts manual, the parts quantity, photos or provide a sample of the parts. Will be served by a business specialist.

| MODEL | TAPE LINES | REED WIDTH | HEALD FRAME | MAX. POWER | R.P.M | REMARK |

|---|---|---|---|---|---|---|

| KDN 2/65 SF4 | 2 | 65 mm | 4+8 | 4.1KW | 500 | 4pcs electronic fram, 8 heald frame. 1 set of 1.1KW brake motor/ 4 sets of 0.75KW server motor |

| KDN 4/55 SF4 | 4 | 55 mm | 4+8 | 4.1KW | 500 |

*We have various models available for the production of slow-stretching webbing. According to the customer's sample, including width, thickness, material, application, function and output. Make it easy for you to produce massively by auto control. Meanwhile guarantee the stability and quality. Fill in the online form to learn more about Kyang Yhe or you can download EDM to know more about technical parameter data.

- Gallery

- KY Needle Loom Spare Parts for Electronic Shedding Frame Assem.

- KY Needle Loom Spare Parts for Dropper Support Assem.

- KY Needle Loom Spare Parts for Weft Head Assem.

- KY Needle Loom Spare Parts for Weft Head Assem.

- KY Needle Loom Spare Parts for Weft Head Assem.

- KY Needle Loom Spare Parts for Dropper.

- KY Needle Loom Spare Parts for Weft Guid Assem.

- KY Needle Loom Spare Parts for Feeder Drive Assem.

- KY Needle Loom Spare Parts for Feeder Drive Assem.

- KY Electron Frame Needle Loom For Slow-stretching Webbing.

- KY Electron Frame Needle Loom For Slow-stretching Webbing.

- Video

- Application

Shock Absorbing Lanyard Loom And Equipment

KY provides complete shock absorbing lanyard production plan and technical consultant, Electron frame needle loom produces high-quality shock absorbing...

- Related Products

Mid-Heavy Automatic Narrow Fabric Ribbon Loom

KDN MG

Automatic Ribbon Loom production of tactical duty belt, cargo lashing, safety harness, etc....

DetailsNewly Electron Frame Needle Loom Machine

ENH SF

ENH SF6 electron frame needle loom is a newly developed machine, for producing shock absorbing...

DetailsSmart Data Collector for Narrow Fabric Weaving Machine

KY-OSDC

Through the smart data collector for narrow fabric weaving machine, real-time operation status...

DetailsIntelligent Active Electronic Warp Let-off System

KY-OEWC

Kyang Yhe's exclusive intelligent active electronic warp let-off system control system is designed...

Details- Files Download

KDN SF Electron Frame Needle Loom Machine

Download EDM know more about Kyang Yhe electron frame needle loom machine

Download

Model

- KDN 2/65 SF4

Reed Width

- 65

KY Needle Loom Catalogue 2025

Download E-Catalogue, know more about KY Needle Loom Equipment.

Particular Electron Frame Needle Loom Machine | Durable Textile Machinery for Zipper, Label, Webbing - Kyang Yhe (KY)

Kyang Yhe (KY), founded in 1964 in Taiwan, manufactures high-quality Particular Electron Frame Needle Loom Machine textile machinery. We specialize in narrow fabric jacquard looms, high-speed needle looms, heavy-duty weaving, braiding, and crochet machines. Get OEM/ODM customization, fast quotations, short lead times, and global service.

Our industrial machines run fast and stable, with easy maintenance. Applications include elastic and ribbon tapes, safety belts, luggage belts, and hook-and-loop. The lineup covers needle looms, narrow fabric weaving machines, label printing machines, and more—built for efficient, consistent production.

With 60+ years of experience, KY provides installation, training, spare parts, and after-sales support. Talk to our engineers today—request a free consultation or quote to choose the right machine for your line.