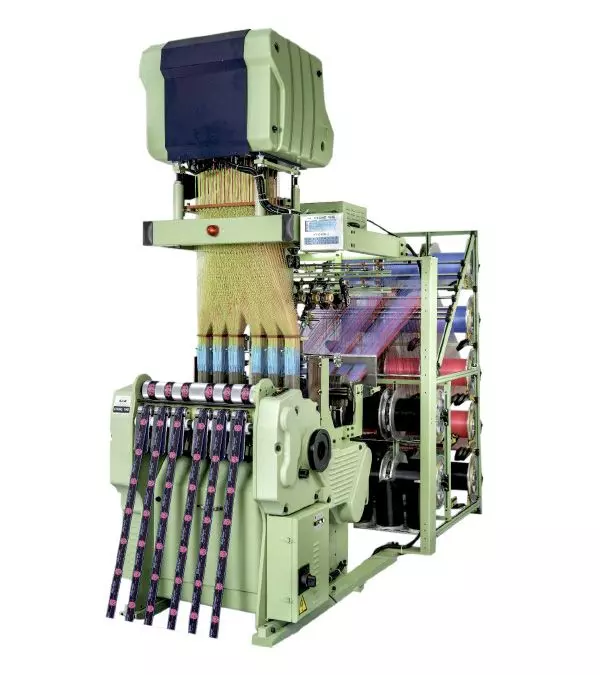

Standard Warping Machine

WM300

Yarn warping machine

The yarn warping machine is applicable to each kind of yarn. Warping can be effected on one of beams at a time special attachments guarantee a perfect uniformity of tension of all ends from the beginning to the end of the warping operation.

In fact, the warping angle is hept constant and the pressure between the drive roller and the beam is brought about by a air pressure between the drive roller and the beam is brought about by a air pressure system, permitting a variation according to require-ments.

A triphase moter provides the drive of the warper. By means of a friction drive the beam can steplessly be put into either forward or backward motion, in order to ease tying of ends.

The machine is equipped with an expansion reed the number of dents of which is determined according to customer's requirements.

Application

Suitable for non-elastic polyester, nylon, polypropylene yarn, etc.

Features

- The warp yarn machine can be used to pass a variety of yarns, each time a pan head (BEAM) can be placed.

- The horsepower by DC motor, and drum drive by the friction drum and beam, the friction is adjustable according to the needs.

- The friction can be adjusted as needed to achieve the desired requirements for the yarn on the beam.

- This machine has special equipment to ensure that the tension is constant from the beginning of the warp to the completion of the warp. It saves yarn waste because it has a Length preset switch.

- The steel shovel equipped with a retractable device can be easily adjusted to save time according to the required density. The automatic disconnection device is convenient for operation.

- Specially designed synchronous motor controlling system and fine-tune system.

| MODEL | BEAM SIZE | CONE CREEL | MAX. POWER |

|---|---|---|---|

| WM300 | MAX: Ø355mm x 255mm | 70~342Ends | 0.75KW |

- Gallery

-

-

KY Warping machine Spare Parts for Beam Bracket Assem. (Drum)

-

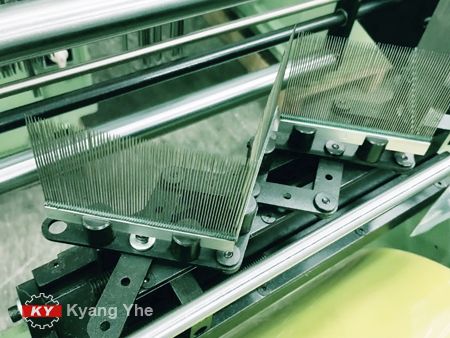

KY Warping machine Spare Parts for Reed Assem.

-

KY Warping machine Spare Parts for Reed Assem.

-

KY Warping machine Spare Parts for Reed Assem.

-

KY Warping machine Spare Parts for Guide Roller Plate Assem.

-

KY Warping machine Spare Parts for Control Panel.

-

KY Yarn Warping machine

-

KY Yarn Warping machine

-

- Video

- Related Products

-

Small Beam Warping Machine

KY-400

KY-400 Warping Machine applies to small beam and high quality operation. Two- step reed to adjust...

DetailsMiddle Beam Size Warping Machine

KY-750

KY-750 Warping Machine applies to middle size beam operating. Two- step reed to adjust the yarn-feeding...

DetailsProofing warping machine

KY-TJX16

Multi- function yarn splitting machine is specialize for the regular weaving sample split yarn...

Details - Files Download

-

Model

- WM300

KY Needle Loom Catalogue 2023

Download E-Catalogue, know more about KY Needle Loom Equipment.

Standard Warping Machine | Maximize Output with Versatile High-Speed Braiding Machines

Kyang Yhe (KY), established in 1964 in Taiwan, is a premier manufacturer of high-quality textile machinery. Specializing in Standard Warping Machine, needle loom machines, narrow fabric jacquard looms, heavy narrow fabric weaving machines, braiding machines, and crochet machines, KY delivers innovative and durable solutions to meet diverse industrial needs. With over 60 years of experience, KY is committed to providing advanced technology and reliable equipment to customers worldwide, ensuring superior production efficiency and quality.

Kyang Yhe (KY)'s industrial textile machines are designed to deliver high-quality knitted products such as elastic tapes, ribbon tapes, safety belts, luggage belts, and hook and loop fasteners. Their textile equipment is productive, high-speed, and easy to operate. The product range includes needle loom machines, weaving machines, label printing machines, weaving loom machines, and more, ensuring efficient and reliable textile production.

Kyang Yhe (KY) has been offering customers high-quality textile machinery since 1964. With advanced technology and 60 years of experience, Kyang Yhe (KY) ensures that customer demands are met effectively.