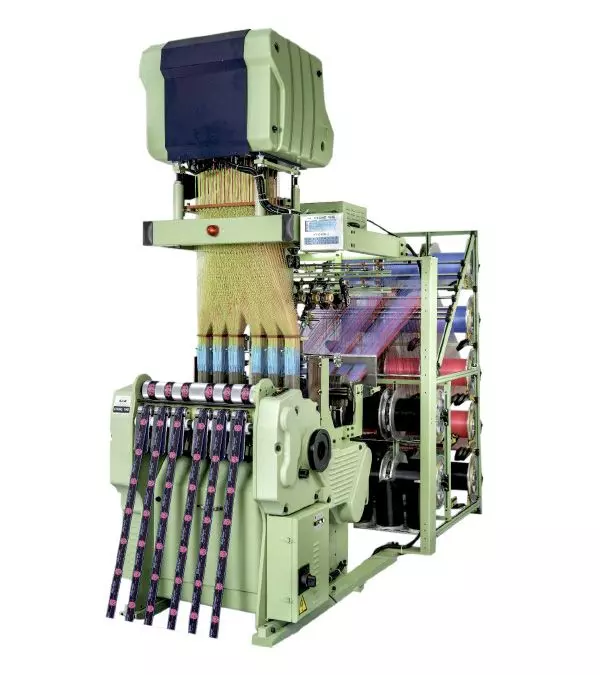

Professional High Speed Zipper Loom Machine

KZP

Zipper needle loom, zipper webbing machine, zipper narrow looms, zipper tape machine

Zipper loom machine application for different match zipper tapes with metal, nylon or plastic zipper. The output have 8 or 10 tape lines, the reed width fixed as 22mm, the weave of the weft density is available from 3.5cm to 36.7cm. Transmission system by belt can high-speed production that without damaging the quality of the woven tapes. The zipper looms with nylon adopt 6 pcs heald frame is different from metal zipper adopt 11 pcs. The machine parts using high quality materials, precision design, durable, a low depreciation rate, to create more economic benefits for customers.

Application

Nylon zipper, metal zipper(size #3. #5 and #8, custom size is OK), plastic zipper, invisible zipper.

Features

- High Speed And High Productivity : A logic design to manufacture the zippers with high speed and high productivity.

- Produce High-Quality Zipper Tape : Precision weaving heads for easy adjustment to meet the demand of high quality control. The woven angle of tape plate bracket at 7.5 degree may improve woven edge more perfect.

- Low Noise Design : Cam shaft and auto lubrication for 24-hour operation free of noise.

- Optimized Belt Transmission Assembly : Accurate discharge of woven tapes by belt transmission, without damaging the quality of the woven tapes.

- High Precision Elements In Refined Design : for high speed operation, long service life and low depreciation.

- Easy Assembly And Adaptation : Fashionable design of the beam creel size for easy assembly and adaptation.

- Stable Operation : Shedding frames are designed by interior-support to fix balance for speed up and more stable.

- Customized Requirements : Back taking-off device and beam creel are changeable according to buyer's requirement.

Optional Function Device

- Back take off device

- Front take off device

- CE certified

- Belt feeding device

- Double-decker device

- To drive the shedding levers by pattern chains

Automatic Needle Loom Accessories

The zipper needle loom function of the shedding motion is driven by a cam system plus auto lubrication which is easy to run for smooth 24 hour operation free of noise. The woven angle of the tape plate bracket at 7.5 degrees may improve woven edge more perfect.

Spare Parts Requirements

If you have zipper loom spare parts requirements, please fill out the form with "Spare Parts Inquiry" and provide ID number of the machine. And also provied the part number according to the parts manual, the parts quantity, photos or provide a sample of the parts. Will be served by a business specialist.

| MODEL | TAPE LINES | REED WIDTH | HEALD FRAME | MAX. POWER | R.P.M | WEFT DENSITY |

|---|---|---|---|---|---|---|

| KZP 8/25-6P | 8 | 22mm | 6 | 1.5HP | 900~1400 | 3.5~36.7cm |

| KZP 8/25-11P | 8 | 22mm | 11 | 1.5HP | 900~1400 | 3.5~36.7cm |

| KZP10/25-6P | 10 | 22mm | 6 | 2HP | 900~1400 | 3.5~36.7cm |

| KZP10/25-11P | 10 | 22mm | 11 | 2HP | 900~1400 | 3.5~36.7cm |

*We have various models available for the production of zipper straps. According to the customer's sample, including width, thickness, material, application, function and output. Make it easy for you to produce massively by auto control. Meanwhile guarantee the stability and quality. Fill in the online form to learn more about Kyang Yhe or you can download EDM to know more about technical parameter data.

- Gallery

- KY Needle Loom Spare Parts for Weft Heads Holder Assem.

- KY Needle Loom Spare Parts for Shedding Frame Assem.

- KY Needle Loom Spare Parts for Feeder Drive Assem.

- KY Needle Loom Spare Parts for Feeder Drive Assem.

- KY Needle Loom Spare Parts for Dropper.

- KY Needle Loom Spare Parts for Roller Assem.

- KY Zipper Needle Loom For Zipper Tape

- KY Zipper Needle Loom For Zipper Tape

- KY Zipper Needle Loom For Customer Factory.

- KY Zipper Needle Loom For Customer Factory.

- KY Zipper Needle Loom For Customer Factory.

- Video

- Application

Zipper Tape Loom And Equipment

KY customizes a complete "Automatic Zipper Tape Production Solution" and recommends best suited machine and purchase plan, to help you be successful in your...

- Files Download

KZP High Speed Zipper Loom Machine

Download EDM know more about Kyang Yhe high speed zipper loom machine

Download

Model

- KZP 8/25-6P

- KZP 8/25-11P

- KZP 10/25-6P

- KZP 10/25-11P

Reed Width

- 22

KY Needle Loom Catalogue 2023

Download E-Catalogue, know more about KY Needle Loom Equipment.

Professional High Speed Zipper Loom Machine | Maximize Output with Versatile High-Speed Braiding Machines

Kyang Yhe (KY), established in 1964 in Taiwan, is a premier manufacturer of high-quality textile machinery. Specializing in Professional High Speed Zipper Loom Machine, needle loom machines, narrow fabric jacquard looms, heavy narrow fabric weaving machines, braiding machines, and crochet machines, KY delivers innovative and durable solutions to meet diverse industrial needs. With over 60 years of experience, KY is committed to providing advanced technology and reliable equipment to customers worldwide, ensuring superior production efficiency and quality.

Kyang Yhe (KY)'s industrial textile machines are designed to deliver high-quality knitted products such as elastic tapes, ribbon tapes, safety belts, luggage belts, and hook and loop fasteners. Their textile equipment is productive, high-speed, and easy to operate. The product range includes needle loom machines, weaving machines, label printing machines, weaving loom machines, and more, ensuring efficient and reliable textile production.

Kyang Yhe (KY) has been offering customers high-quality textile machinery since 1964. With advanced technology and 60 years of experience, Kyang Yhe (KY) ensures that customer demands are met effectively.